EN 1363-1

Fire resistance tests –Part 1: General Requirements

The purpose of the method described in the European standard is to determine the behavior of a construction when subjected to a defined heat load and pressure.

The method provides the ability to quantify the capacity of an element, or a construction, to withstand high temperatures using functional requirements such as carrying capacity, density and thermal insulation to provide a few. The method provides the general requirements for fire resistance testing and is usually used in conjunction with other product-specific test standards. In this method, the default fire curve is defined.

esting can be used for type approval and CE marking for designs where a product standard or a European Technical Approval Guideline (ETAg) is available.

Brief description of the method

The test itself takes place in a furnace which has an opening on which the test object is mounted. The furnaces at RISE Fire Research have a 3 x 3 m opening for testing vertical structures such as walls or fire doors and 5 x 3 opening for testing horizontal structures such as tile floors or ceilings. The furnace is then heated according to a defined time-temperature curve which represents a real fire where you get an overrun.

The method describes how the construction is to be mounted and how to position and mount the measuring equipment to be used.

The standard also sets out the requirements for accuracy of the measurements made and the instruments used. This may be, e.g. thermocouples, pressure sensors and deformation meters. The method also describes various types of connecting structures, as walls in which the test object, such as a fire door, must be mounted. Furthermore, the standard describes how to verify that the tested design complies with the drawing.

One common procedure is that the customer submits two test items, of which one is selected for testing and the other one is used for checking and verifying the design. Another important aspect described in the standard is how different designs should be conditioned before testing, ie how long they are to be stored in a certain climate. Finally, the standard contains instructions on what the test report should contain.

EN 1364-1

Fire resistance tests for non-load-bearing elements – Part 1: Walls

European fire test method for non-load-bearing walls.

This part of EN 1364 specifies a method for determining the fire resistance of non-load-bearing walls. The standard is to be applied in conjunction with EN 1363-1.

The method can be applied to non-load-bearing inner walls with or without glazing, walls consisting mostly of glass and other inner or outer walls with or without glazing. The method is also applicable to windows.

If, in practice, the width or height of the construction is 3 m or less, then that dimension of the test specimen shall be tested at full size. The tested object must be constructed as in practice. According to the standard, different design solutions may not be mixed in a test such as different types of glass if it does not conform to the design solution used in practice. If, in practice, the construction is less than 3x3 m, the wall must be attached in the same way as in practice. Otherwise, a vertical side should be free and the remaining three sides will be attached as in practice.

For constructions with an anticipated insulation performance, thermocouples are mounted on the non-exposed side for measurement of average temperature and maximum temperature. The integrity of the structure is measured as usual with interpreters, cotton pad and visual observations.

For vertical constructions there are also other functional requirements that can be used for classification. Radiation can be measured on uninsulated test items (for E-Class) and on test items having uninsulated areas greater than 0.1 m2, and where the surface temperature of the non-exposed side is expected to exceed 300 °C. The deformation of the wall shall be measured for later use as a basis for assessments.

Some countries, such as Sweden and Germany, require shock resistance, in this case shock tests must be performed according to EN 1363-2.

Performance characteristics

E - Integrity, I - Thermal Insulation, W - Radiation, M - Mechanical action

The classification standard EN 13501-2 defines the classes that can be used in Europe and the classes in the table below can be applied to non-load-bearing walls. National authorities in the member states may choose not to use all classes why it is important to check which classes are of interest before testing.

Fire protection ability classes non-load-bearing walls

|

Intended fire resistance |

Time (minutes) |

||||||||

|

E |

- |

20 |

30 |

- |

60 |

90 |

120 |

- |

- |

|

EI |

15 |

20 |

30 |

45 |

60 |

90 |

120 |

180 |

240 |

|

EI-M |

- |

- |

30 |

- |

60 |

90 |

120 |

- |

- |

|

EW |

- |

20 |

30 |

- |

60 |

90 |

120 |

- |

- |

For our full range of technical specifications please click on relevant headings below

Ballistic Technical Specifications

EN 1063 Glass in Building - Security Glazing - Testing and Classification of Resistance Against Bullet Attack

UL 752 Standard for Bullet-Resisting Equipment

BS 5051 Bullet-resistant glazing - Part 1: for interior use- Part 2: for Exterior use

NIJ 0108.01 US National Institute of Justice Standard-Test and Certification for Ballistic Resistant Materials

EN 1522/3 Windows, doors, shutters and blinds - Bullet resistance - Requirements and classification /Test method

Blast Specifications

GSA-TS01:2003 Standard Test Method for Glazing and Window Systems Subject to Dynamic Overpressure Loadings

EN 13541 Glass in building - Security glazing - Testing and classification of resistance against explosion pressure

EN 13123-2 Windows, doors and shutters - Explosion resistance - Requirements and classification

ISO 16933:2007 Glass in Building -- Explosion-Resistant Security Glazing -- Test & Classification for Arena Air-Blast Loading

Fire Specifications

UL 10C Positive Fire Pressure Tests of Door Assemblies

BS 476 Part 22 Fire tests on building materials and structures

EN 1634-1 Fire resistance and smoke control tests for door and shutter assemblies, openable windows and elements of building hardware

Manual Attack Specifications

EN 1627 Pedestrian door-sets, windows, curtain walling, grilles and shutters - Burglar resistance - Requirements and classification

LPS 1270 Intruder Resistant Security Glazing - Requirements & Testing Procedures

LPS 1175 Requirements and testing procedures for the LPCB certification and listing of intruder resistant building components, strongpoints, security enclosures and free-standing barriers

EN 356 Glass in building - Security glazing - Testing and classification of resistance against manual attack.

LPS 1175 and 1270 Tool Categories Testing procedures for the LPCB approval

This is an extract not a full report and Architectural Armour Ltd accepts no liability for any loss, direct, indirect or consequential damage incurred by using this information, to the fullest extent permitted by law. You should make your own judgement as regards use of this document and seek out the full test standards.

Latest News

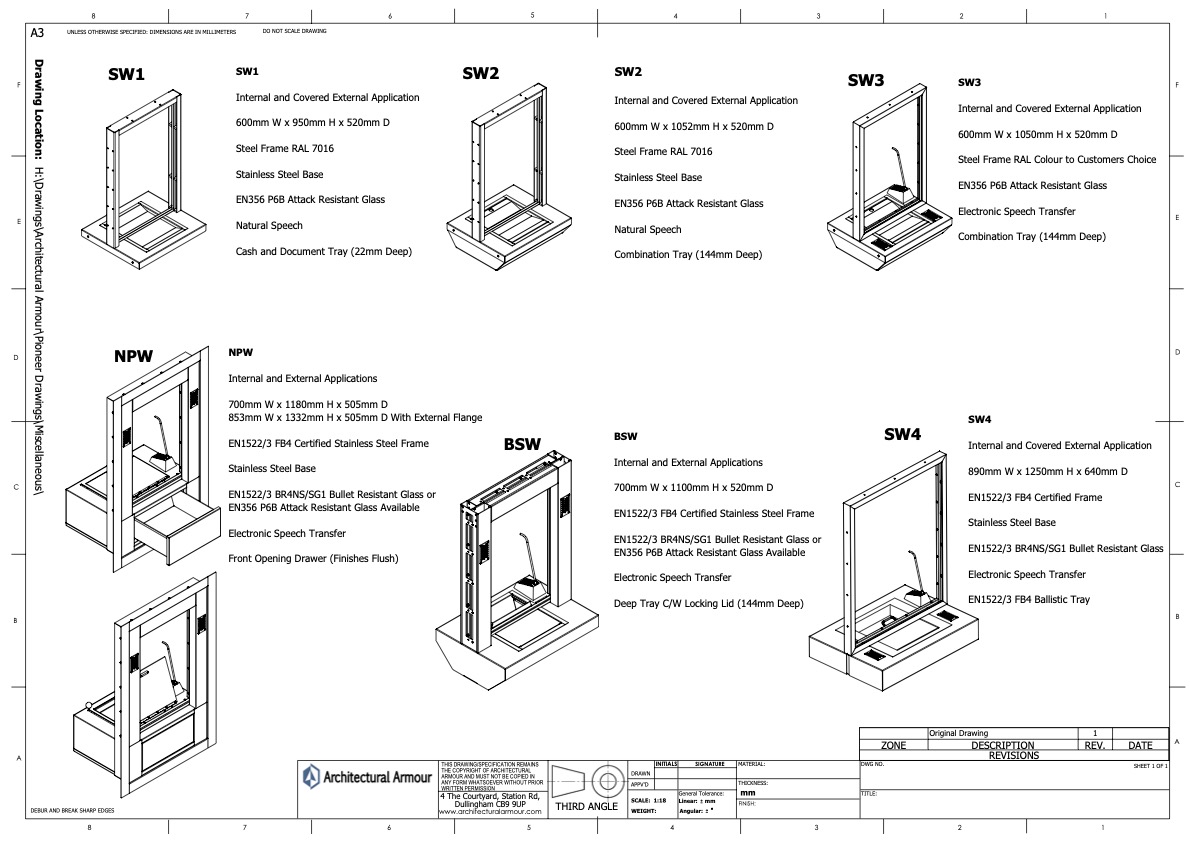

Split Height Transaction Window Duo

Using experience on previous projects and customers requirements we have designed a split height transaction window offering standing and DDA access to reception and data centre environments.

For more information and pricing please contact our office on info@architecturalarmour.com or +44(0)1981 257000

Read more

Increased Stock for Express Delivery

We have increased our range of stock transaction windows to six units , ready for express dispatch.

Our range of transaction windows include, physical attack resistant and bullet resistant internal and external models. Please see below an outline of our products.

Architectural Armour are offering standard stock items and bespoke orders to suit. Please contact us on +44(0) 1981 257000

Read more