Attack Resistant Glass

Attack Resistant Glass

Architectural Armour offer a range of laminated Attack resistant glass products, typically these are manufactured to meet current standards both international, EN356 and UK LPS 1270. Attack resistant glass is usually comprised of multiple layers of either float or toughened glass laminated together. Some products, to allow for thinner constructions or a safer construction incorporate polycarbonate. They are available as stand alone laminated panes or can be incorporated into Double Glazed units for fire or thermal efficiency.

If your requirement is for a complete window assembly please visit Attack / Intruder Resistant Windows

Below we indicate the standards, glass weights and thicknesses we offer, with further explanation lower down the page.

EN 356

Attack Resistant Glass Available to EN 356 European Standard for Glass in Building

Higher Level

The list below shows the glass we can supply, with attack level resistance ranging from 30 blows to 71 blows before a 400mm sq hole is achieved. To view specific glass data sheets please click on the specification you require in the table below.

| Sledgehammer & Axe Blows | Constructions Available | Glass Thickness (mm) | Weight per m2 (kg) | Link to PDF | |

| BS EN 356 P6B | 30/50 | Glass/PVB | 15 | 46 |  |

| Glass/Poly/Glass | 10 | 23 |  |

||

| BS EN 356 P7B | 51 | Glass/PVB | 28 | 67 |  |

| Glass/Poly/Glass | 16 | 33 |  |

||

| BS EN 356 P8B | 71 | Glass/PVB | 26 | 57 |  |

| Glass/Poly/Glass | 18 | 35 |  |

Lower level

This is a hard body drop test using a 4.11 kg steel sphere (100mm diameter) to represent a blunt instrument such as a hammer attack.

| Drop Height (mm) | No of Strikes | Impact energy Per Stroke (J) | Glass Thickness (mm) | Weight per m2 (kg) | |

| EN 356 P1A | 1500 | 3 | 62 | 6.8 | 16 |

| EN 356 P2A | 3000 | 3 | 123 | 8.8 | 19 |

| EN 356 P3A | 6000 | 3 | 247 | 9.1 | 21 |

| EN 356 P4A | 9000 | 3 | 370 | 9.5 | 21 |

| EN 356 P5A | 9000 | 9 | 370 | 10.3 | 21 |

Other Physical Attack Glazing Standards

LPS 1270 Intruder Resistant Security Glazing - Requirements & Testing Procedures

LPS 1270 was developed by LPCB to certify glass products to be compatible with LPS 1175. LPS1270 differs from EN 356 in that the test is carried out by a person able to vary his choice of tools and method of attack, within the duration of the test. LPCB believe this better represents an actual attack rather than the robotic method used in EN356. The result is to provide a range of tested categories, dependent on the tools allowed and the duration of the test, the higher categories’ of which exceed those of EN356.

LPS 1270 Intruder Resistant Glass |

Thickness |

Weight (kg/m2) |

LPS 1270 - 001 |

16.5mm |

37 |

LPS 1270 - 012 |

20.5mm |

38 |

LPS 1270 - 013 |

22.5mm |

41 |

LPS 1270 - 123 |

26.5mm |

46 |

LPS 1270 - 113 |

34mm |

61 |

LPS 1270 - 224 |

42mm |

72 |

LPS 1270 - 234 |

45mm |

71 |

LPS 1270 - 235 |

60mm |

100 |

How is Attack Resistance Achieved

Laminated glass

Laminated glass can be designed to withstand a varied level of attack by mixing the glass thickness for strength and the amount of interlayer that binds the glass together to improve penetration resistance. Even when broken laminated glass can still provide protection and slow the would be assailant down.

We offer physical attack resistant glass in a variety of multiple laminate compositions in thicknesses from 6.8mm to 60mm to defeat hammer, axe and even power tools. These can be combined for thermal and fire efficiency with other certified products, either by lamination or incorporation into DGU's .

Types of Attack Glass

There are 2 main types of laminated attack glass compositions.

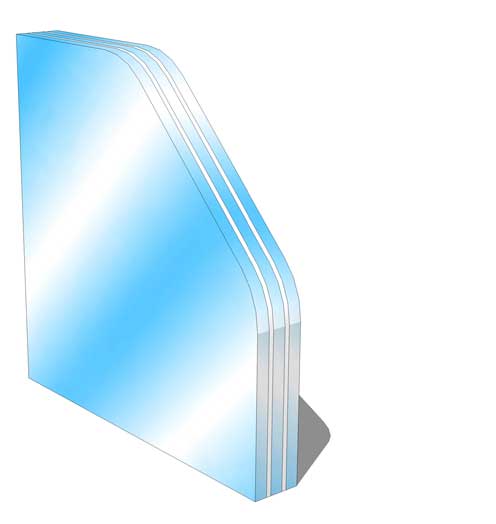

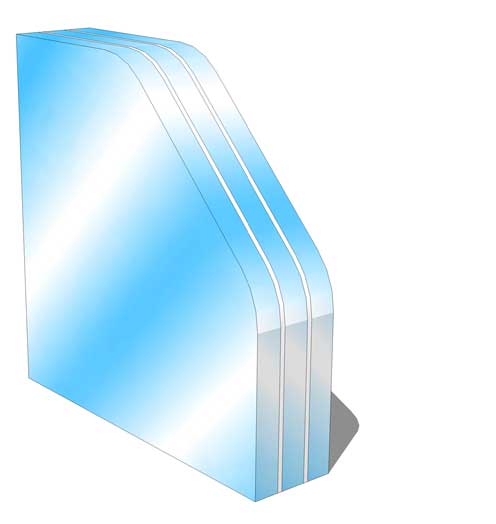

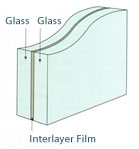

Glass/PVB/Glass

These laminated products are manufactured by sandwiching layers of polyvinyl butyral ( PVB ) between either float, heat strengthened or toughened glass dependent on application. The bonding process typically takes place in an autoclave where the heat and heat and pressure make the PVB interlayer become optically clear. The laminated glass behaves as a single unit and is normal in appearance to single pane glass. The PVB is strong and flexible bonding the glass layers to it even when distorted in an attack.

Attack rated glass may consist of any number or combinations of thicknesses of glass bonded into a single unit. Most common are 3 ply but they can be as many as 7

3 ply Glas /PVB/Glass (2 panes and 1 interlayer) e.g. 6.8mm 3mm/0 .76PVB/3mm ,

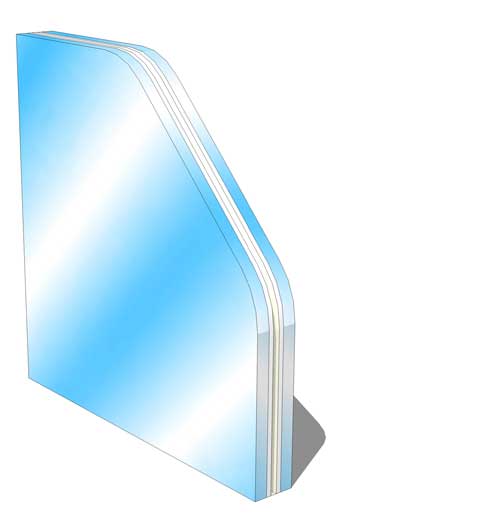

Glass / Polycarbonate / Glass

Glass polycarbonates utilise a layer of polycarbonate sheet centrally located between the outer panes of glass. The thickness of the polycarbonate will vary according to desired specification, ranging from 1mm in an EN356 P6B to a 12mm in an LPS 1270 glass . The glass poly glass laminates do not use PVB interlayer but a PU ( polyurethane) to adhere the polycarbonate to the glass.

Strength

Polycarbonate is a clear thermoplastic that is strong and can resist repeated manual attack hence it is used for the manufacture of riot shields, safety helmets and more. The downsides of polycarbonate are that it scratches and is not resistant to some chemicals, by placing the polycarbonate between two panes of glass these problems can be removed.

Reduced thickness and weight

To achieve higher levels of attack resistant glass using the conventional Glass/PVB/Glass methods you have to increase the thickness and thus weights. Glass poly glass compositions are thinner and lighter and more attractive to many glaziers who wish to use them in existing shopfronts which may have traditionally had 11.5mm glazing.

A word of caution

All physical attack resistant glasses are only as good as the frames they are situated in, most important is the amount of “edge cover” or “bite”. This is the amount the frame overhangs the glass at the edges, too many times we see small glazing beads often only 12mm high holding in the glass which when you allow for a tolerance gap may only be covering the edges by 6mm. Whilst the need is not as great as the 30mm plus we require for blast glass I would recommend 15mm glass coverage as a minimum.

The need for replacement of traditional jewellers shopfront glass for the glass poly glass specifications has been increasingly driven by insurers for the last 10 years, but with jewellers shops being attacked almost daily the need is now even greater and most insurers are specifying EN356 or LPS 1270 products.

With such a diverse range of glazing options to choose from we advise you to contact us to discuss your specific glazing requirements. Please call +44(0) 1981 257000 or mailto:info@architecturalarmour.com

BS5544 Anti-Bandit Glazing (Glazing Resistant to Manual Attack)

BS5544: 1978 (1994), is the UK standard for anti-intruder glazing. Although the standard was developed to represent an attack by a blunt instrument such as a hammer, the test comprises multiple drops of a steel ball from varying heights. The ball must not penetrate the glazing in either test. It is a straight forward pass or fail test and thus gives no indication of the number of blows or the time required to achieve penetration.

For many years an industry favourite has been 11.3mm 5ply, this was developed to comply with BS5544

Security or Safety Glass ?

Security Glass is a broad term used to describe multiple products that ultimately offer people or possessions protection against a threat. The term can cover a multitude of capabilities but primarily Architectural Armour offer high security Attack Resistant, Bullet Resistant, Blast Resistant and Fire Resistant glass and glazed assemblies. Security Glass is produced worldwide using many different manufacturing methods, as a result there is often some confusion as to which construction is most suited to which application.

To help explain it’s probably best to give a brief guide of the most commonly used types of glass, and how some are used in the manufacture of security glazing systems.

Float Glass

Float glass is a single monolithic piece of flat glass; it’s made by floating molten glass on a bed of molten metal to give the sheet a uniform thickness and very flat surface. When used on its own, float glass has almost no security value as it’s easily broken and breaks into large, jagged shards.

Toughened Glass

Toughened glass is manufactured by subjecting the float glass to a heating and cooling treatment. A balance of high compressive stresses at the surface and tensile stresses in the centre of the glass increases its strength. The result is a glass that is approx. 5 times stronger than ordinary glass of the same thickness, but it can be easily broken by an impact such as a ball hammer, where upon it breaks into small, blunt-edged fragments instead of splintering into jagged shards. When used alone it could be considered safety glass but has little security value as it leaves nothing in place to protect your assets.

Laminated Glass

Laminated glass is manufactured by bonding together two or more layers of high quality float glass under heat and pressure using an interlayer such as polyvinyl butyral (PVB). In this instance the PVB serves to maintain the integrity of the glass following deliberate or accidental damage. Dependent on the make up of the laminated glass, it could be considered a safety, attack or bullet resistant glass.

Laminated Safety Glass

Laminated safety glass is intended for use in architectural applications where in the instance of accidental damage the use of monolithic glass would present a hazard. Laminated safety glass may crack locally following impact, but will retain its' integrity. Typically, Laminated Safety Glass is a 3 ply construction, consisting of two layers of glass sandwiching an interlayer, the thickness of both the glass and PVB can be varied to give a number of different options dependent on application, but even when laminating toughened or heat strengthened glass they do not always provide the level of integrity of multiple layered constructions you can find in bullet resistant glazing.

Laminated Security Glass

Security Glass is a broad term used to describe multiple products that ultimately offer people or possessions protection against a threat. The term can cover Bullet Resistant, Blast and Manual Attack glass to name but a few. Standard laminated glass can even offer a degree of security compared to a single toughened or float panel.

Architectural Armour can supply all of the above glass options into a wide variety of glazed security products. If you have any questions about your requirements, please feel free to email mailto:info@architecturalarmour.com or call us on +44(0)1981 257000 .Architectural Armour offer a range of attack resistant products to different standards, please click the relevant link below to find out more;

Manual Attack Resistant Stock Items

Night Pay Window / Hatch A flat fronted Transaction Window with opening drawer, typically uses Petrol Stations and Pharmacies

Attack Resistant Transaction Windows 2 types of versatile Physical Attack Ticket/Cashiers windows with Natural Speech Path for internal use

All of the above can also be manufactured in bespoke sizes.

Bespoke items with Glass

Security Counters and Screens Physical, Ballistic or Blast resisting counters for any application to keep staff secure

Attack/Intruder Resistant Doors LPS1175 rated doors for multi-purposes. Manufactured bespoke to customers requirements

Attack Intruder Resistant Windows EN356 rated attack resistant windows protecting against planned or surprise attacks.

Manual Attack Specifications

EN 1627 Pedestrian door-sets, windows, curtain walling, grilles and shutters - Burglar resistance - Requirements and classification

LPS 1270 Intruder Resistant Security Glazing - Requirements & Testing Procedures

LPS 1175 Requirements and testing procedures for the LPCB certification and listing of intruder resistant building components, strongpoints, security enclosures and free-standing barriers

EN 356 Glass in building - Security glazing - Testing and classification of resistance against manual attack.

LPS 1175 and 1270 Tool Categories Testing procedures for the LPCB approval

Latest News

Split Height Transaction Window Duo

Using experience on previous projects and customers requirements we have designed a split height transaction window offering standing and DDA access to reception and data centre environments.

For more information and pricing please contact our office on info@architecturalarmour.com or +44(0)1981 257000

Read more

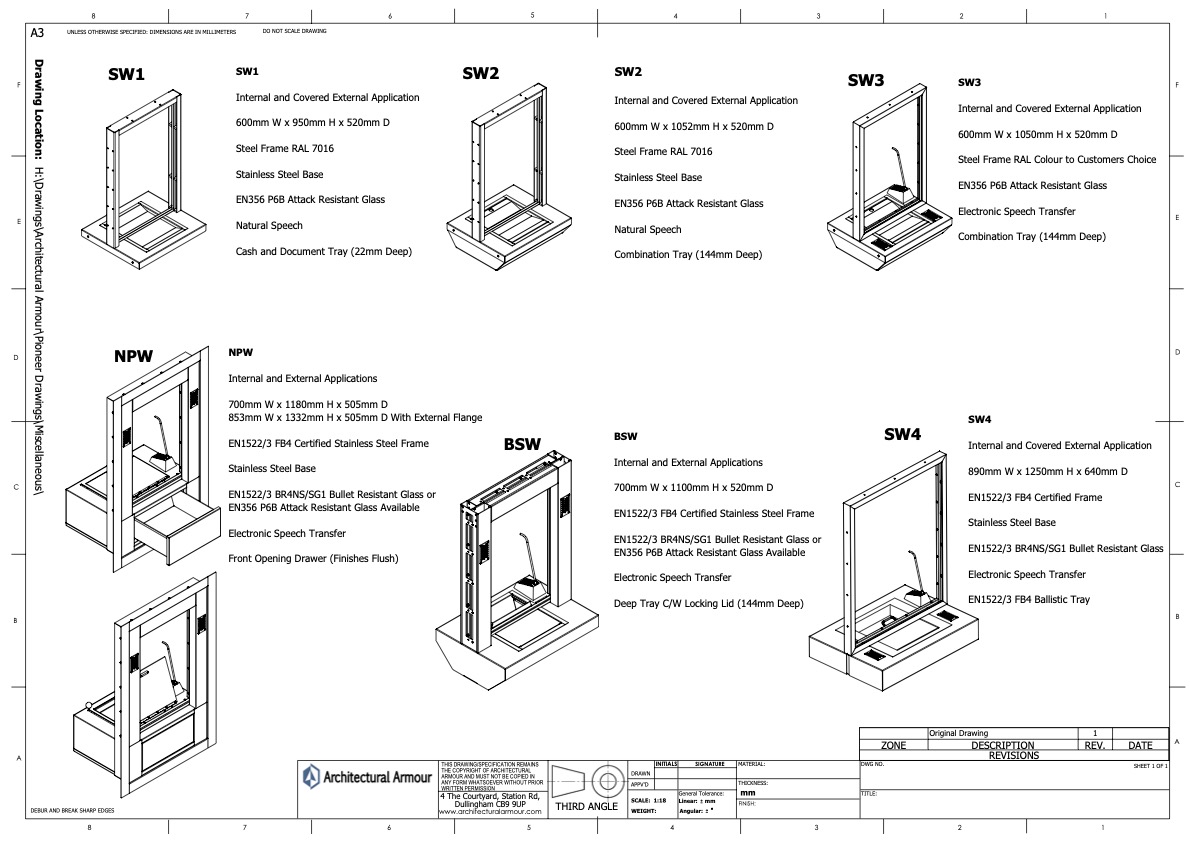

Increased Stock for Express Delivery

We have increased our range of stock transaction windows to six units , ready for express dispatch.

Our range of transaction windows include, physical attack resistant and bullet resistant internal and external models. Please see below an outline of our products.

Architectural Armour are offering standard stock items and bespoke orders to suit. Please contact us on +44(0) 1981 257000

Read more